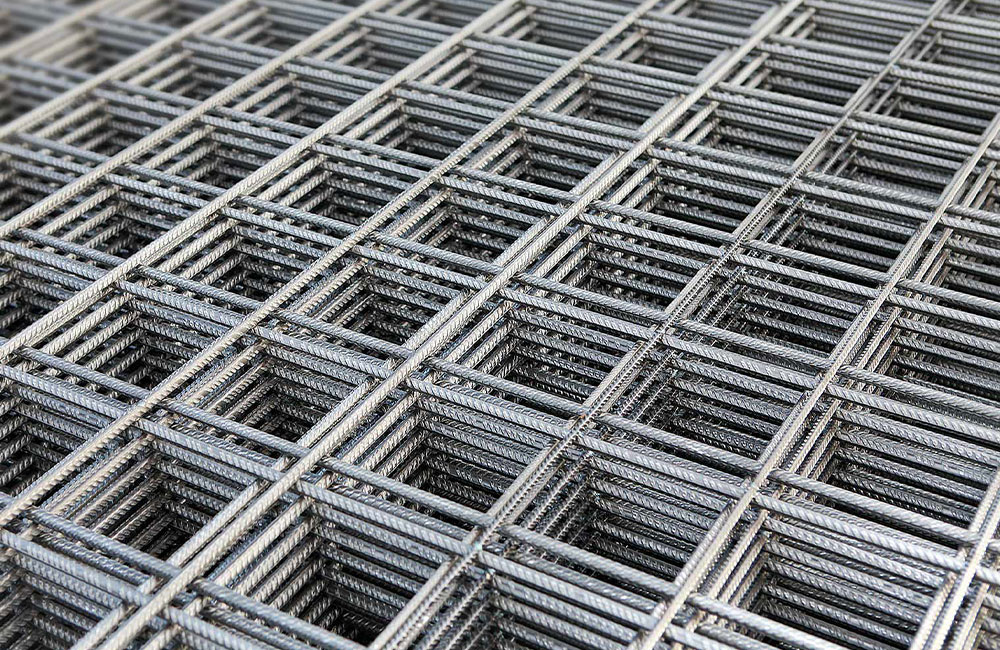

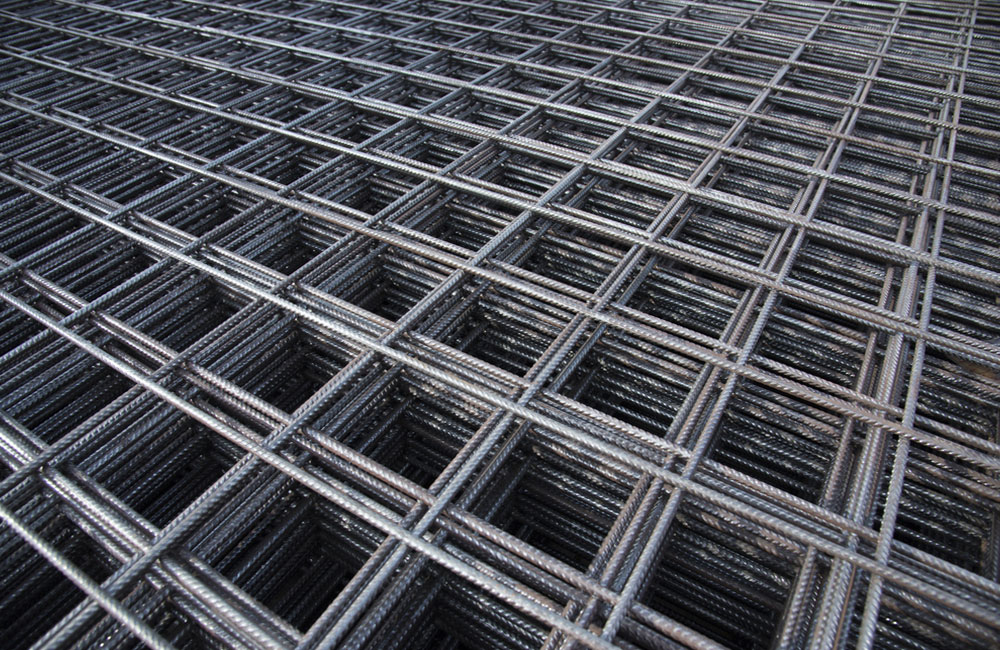

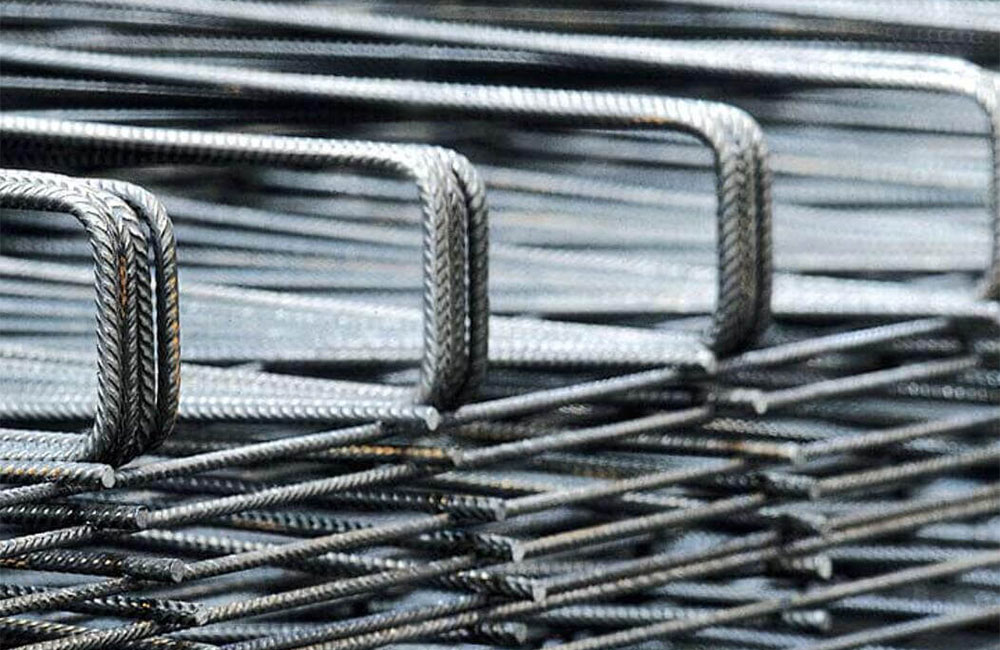

Ignoring the manual wire mesh weaving steps, Dai Nghia believes that our products will help contractors speed up the construction progress of items related to Steel Welded Wire Mesh. Therefore contributing to speeding up the construction progress.

Brochure

ReferProducts

PRODUCTION - QUALITY CONTROL PROCESS

1. Check certificates

2. Check CO/CQ

1. Check steel grade

2. Check steel diamete

1. Check steel surfafe after stretching

2. Check steel diameter after stretching

3. Check steel intensity after stretching

1. Check steel length

2. Check straightness

3. Check surface, bonded

1. Check the dimension of drawing

2. Visual checking: welded joint and the square of welded mesh.

1. Check the length of excess head and the angle in comformity with shop drawing.

1. Overall checking for welded mesh

2. Check stamp and quantity as order

3. Pack welded mesh in according to weight of product

With professional and experienced team, the quality management system ISO 9001:2015; ISO 14001:2015; ISO 45001:2018 and the factory scale of around 35,000m2 to equipped modern steel structure production lines.

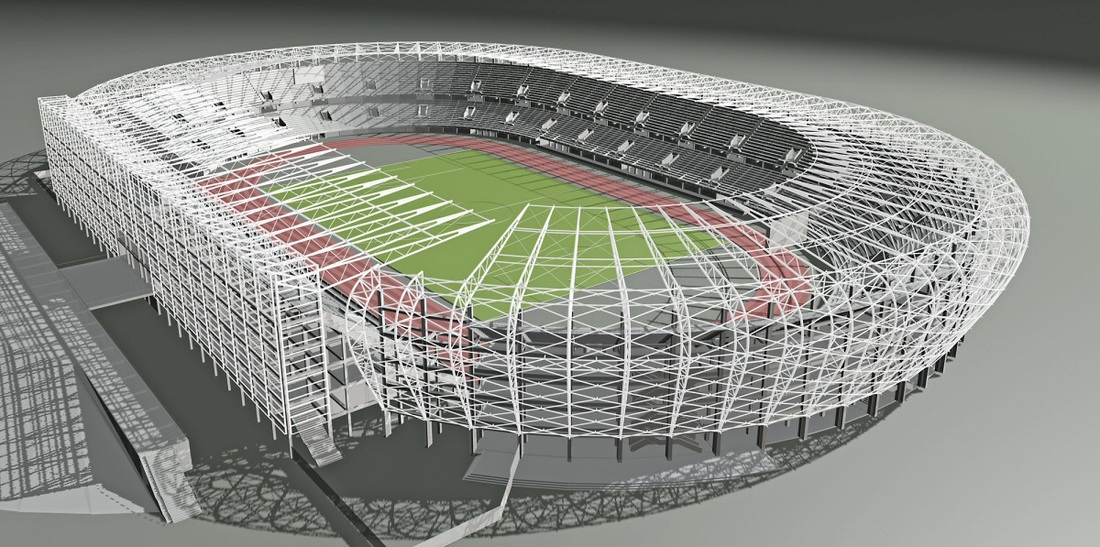

Dai Nghia is committed to providing a variety of choices, including factories, warehouses, high-rise buildings, heavy industrial projects, commercial centers, exhibition centers, stadiums, and infrastructure transportation, railway stations, airports, ... to customers. In addition, we also have a factory specializing in manufacturing steel welded wire mesh and supplying high-quality construction steel for domestic and overseas.

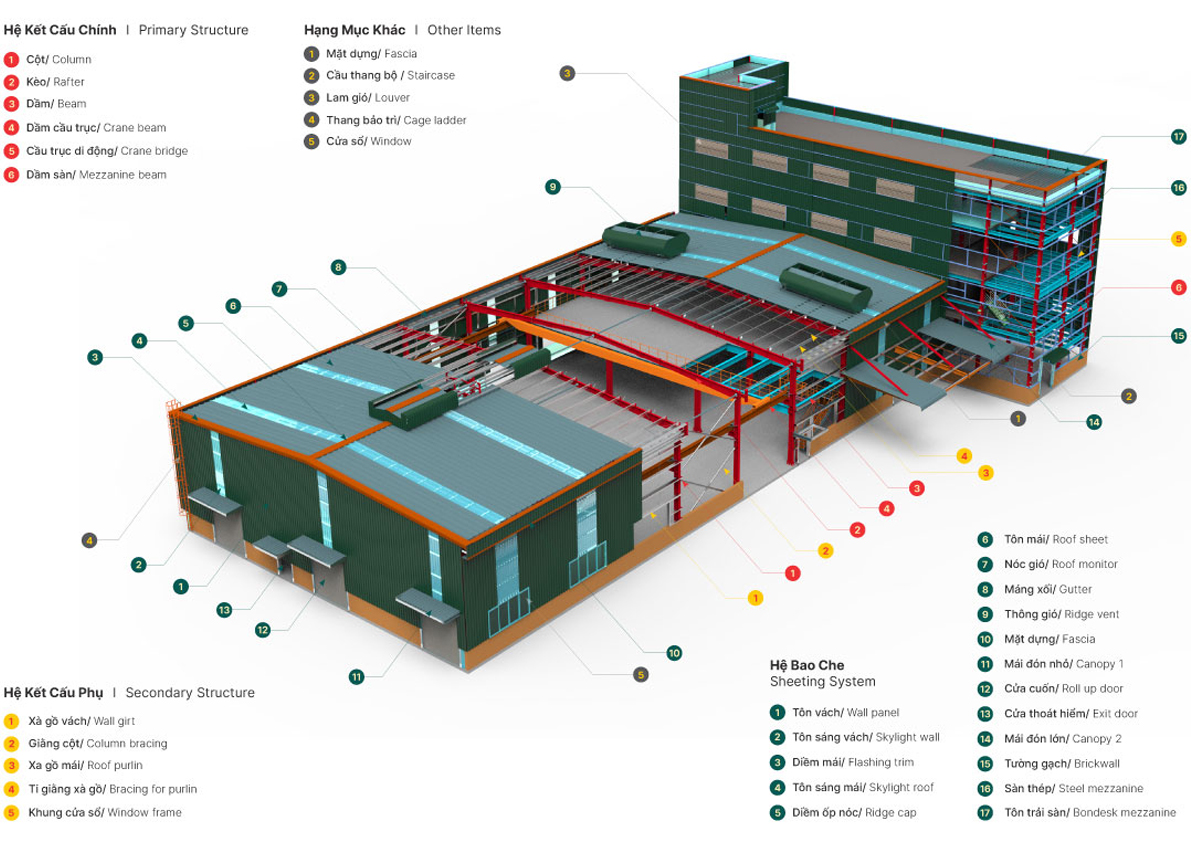

Structure

Pre-engineered steel building (also known as pre-engineered house) is a type of building built with a steel frame and installed according to technical architectural drawings. The entire structure of the pre-engineered steel building is pre-manufactured, so the erection can take place very quickly. The buildings that often use this type of house can be mentioned as: warehouses, factories, supermarkets, showrooms, high-rise buildings, commercial buildings...

ADVANTAGES OF PRE-ENGINEERED STEEL BUILDING

All steel members are connected by bolts, connecting sections have been designed beforehand from raw materials in stock.

Reduce foundation cost due to light weight structure and shorten construction time

Reducing loads on foundation and offer greater resistance to seismic forces

All components have been produced in factory and shipped to construction site to be erected by bolts. It can educe total construction time by at least 1/3 in compared with concrete buildings.

All steel members are manufactured in a factory with strict quality control. Then they are coated with high quality paint to increase the durability and lower maintenance cost.

Optimize using space compared with concrete structures in public constructions: trade centers, exhibition centers, airports, stadiums,...

APPLICATION OF PRE-ENGINEERED STEEL BUILDING

What is structural steel?

Structural steel is a metal structure formed from interconnected steel* members to transmit and bear forces. Thanks to the high strength of steel, this structure is very strong and requires less material than other types of structure such as concrete structure or wooden structure.

In modern construction, structural steel is used for almost all types of structures including heavy industrial buildings, high-rise buildings, equipment support systems, infrastructure, bridges, tower, airport, racking system

Factory at: Dai Nghia Steel Joint Stock Company

Address: No. 23, Street 16, Vinh Loc Residential Area, Binh Hung Hoa B Ward, Binh Tan District, City. Ho Chi Minh City

PRODUCTION - QUALITY CONTROL PROCESS

1. Import steel plate

2. Import steel section

3. Inspection

1. Cutting steel plate

2. Inspection

1. Drilling gusset plate

2. Drilling steel section

3. Inspection

1. Auto cutting

2. Inspection

1. Auto welding

2. Inspection

1. Straitening element

2. Inspection

1. Finishing welding element

2. Cleaning by hand

1. Shot blasting

2. Painting elemen

3. Inspection

1. Marking

2. Inspection

3. Delivery to site

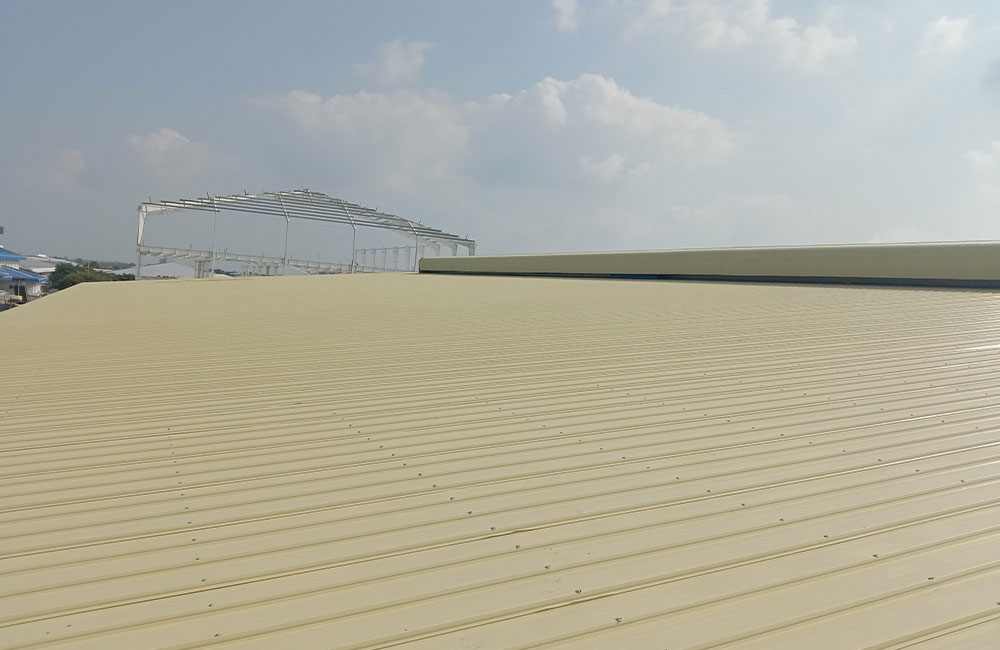

Besides ensuring the construction progress with steel truss frames, Dai Nghia also helps speed up the completion of pre-engineered steel buildings by investing in production lines and covering systems including corrugated iron & high-quality purlins. high quantity.

With many projects stretching from central to southern Vietnam. Dai Nghia's corrugated iron & purlin products have contributed to speeding up the project progress and putting the project into use according to the customer's plan.

Our corrugated iron & purlin products meet TCVN & international standards and are manufactured & quality checked according to ISO 9001:2018 process.

With many options suitable for each need in terms of corrugated iron such as: 5 waves, 9 waves, 11 waves, cliplock, seam, decking corrugated iron and many specifications C purlin, Z purlin. Customers completely have You can rest assured that the quality & price is suitable for your needs.